Thermal Barrier Coatings with FDM

Thermal barrier coatings (TBCs) are commonly used in aerospace, marine, and industrial turbines for both production and repair work. They help improve corrosion and oxidation resistance, prevent wear and erosion, and add to the thermal stability of surfaces. Therefore, TBCs are a popular choice for increasing the service life of individual components and entire products. Another notable benefit is improving system efficiencies by enabling higher operating temperatures.

Problems With Traditional Masking

TBCs are expensive and only need to be applied to critical surfaces that would benefit from the treatment. An example of this would be the interior of gas turbine combustor liners or the blades of turbine spools; mating surfaces on these components must be left uncoated. This requires time-consuming and costly masking of these areas.

To achieve this, traditional methods rely on high temperature-resistant tape and silicone masking. Drawbacks include the high cost of this non-reusable tape, long lead times for outsourced silicone masks to be made, and a large amount of labor to carefully apply the tape by hand to each individual component.

Silicone hard masking offers only minimal advantages over taping as it is often designed and purchased through external suppliers, which drives long lead times and high costs. Often, the designs require iteration to ensure a good fit resulting in further delays and money wasted.

Advantages of the FDM Solution

Additive manufacturing with FDM® materials’ excellent mechanical properties and high thermal performance coupled with Fortus® 3D printer reliability and repeatability represent a viable alternative to the traditional masking processes.

Fortus systems offer a masking solution that is both reusable and has shorter lead times. This is because of FDM technology’s ability to enable tooling to be designed and manufactured in-house from high-temperature polymers such as ULTEM™ 1010 resin. Furthermore, unlike CNC processes, FDM technology lacks the need for extensive toolpath programming or physical tooling, meaning design changes can be made at the last minute with almost no downstream effect on production.

Offering both economical and lead-time advantages, FDM technology provides a completely new and more efficient way to produce masks over traditional processes. It is also applicable to other masking needs such as spray painting, shot peening, hard facing, and spray welding.

Application Validation

To validate this application, tests were carried out on the coating of tool steel using a plasma spraying process with a Tribaloy 800 coating with masks made from both ULTEM™ 1010 and ULTEM™ 9085 resins. These tests were successful and are summarized at the end of this document, where you will find recommended design and printer settings from which to base your own designs.

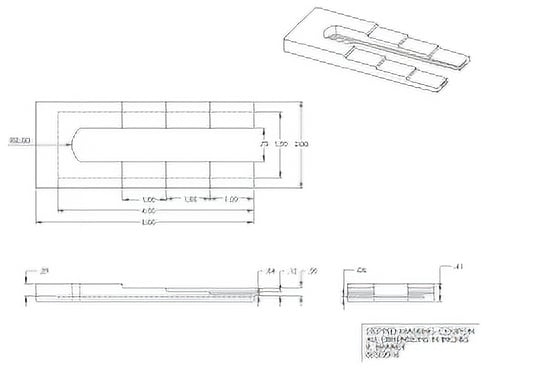

Mask Geometry

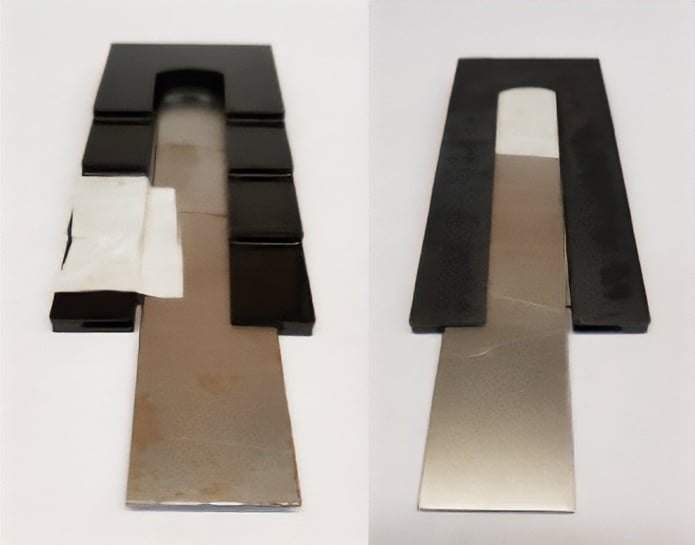

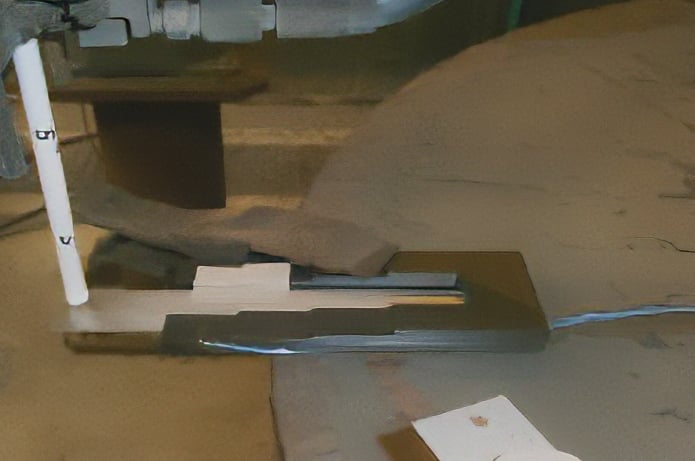

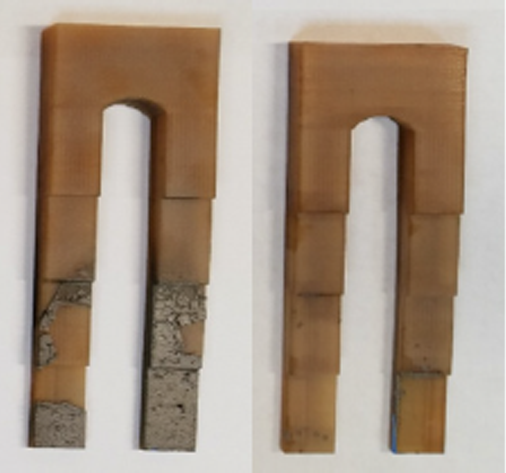

The FDM masking samples were loaded with a tool steel blank and held in place with the help of the high-temperature tape as backing.

The masks have four steps, with the thinnest step being Step 1. This was carried out to establish a minimum recommended mask thickness.

Test Procedure

The investigation consisted of the following phases:

- Printing of the masks

- Epoxy coating of half the masks

- Measurement and evaluation of masks before spraying

- Thermal spraying of the tool steel blanks in FDM masks

- Measurement and evaluation of masks after spraying

- Restoration and cleaning of masks for further use using grit media blasting

- Measurement and evaluation of masks after restoration

The physical test setup was done on a rotating bed with samples equally spaced along the perimeter. The samples were attached to the rotating bed by using 50.8 mm (2.0 in.) spring clamps.

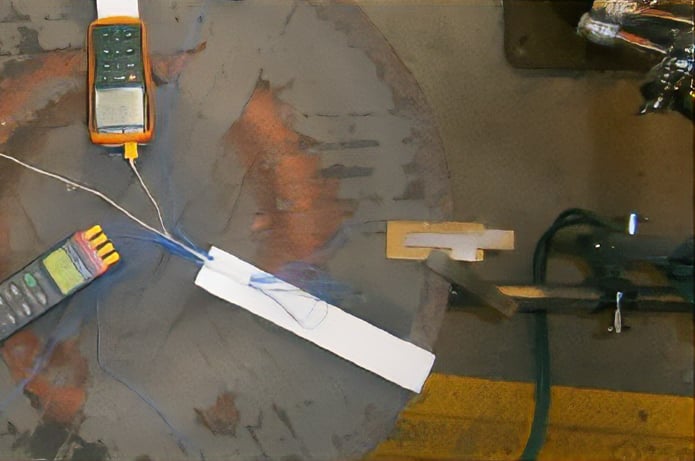

A robotic setup was used to apply the coating evenly across all samples. Samples were attached, equally spaced, to the perimeter of a bed rotating at 45 RPM under a robotic application arm. The spray gun had a standoff of five inches aimed normally at the samples. TBC application included three pre-heat passes and 25 coating passes to build up the coating to 0.457 mm (0.018 in.).

The following questions were asked as part of the investigation.

What temperatures do masks experience during a typical thermal spray coating process and how suited is ULTEM™ 1010 resin to this thermal exposure?

K-type thermocouples were attached to the FDM mask using a small amount of Kapton tape. Data loggers recorded the temperature during the thermal spraying operation. If temperatures are found to be below the heat deflection temperature of the material, this gives a good indication that the masks will be thermally stable enough for this application.

How do mask surface roughness, thickness, and mass vary throughout the thermal spraying and restoration phases?

The surface roughness, thickness, and mass of the mask were measured throughout the investigation to establish the stability of the mask after being exposed to the harsh environment of the thermal spraying process. It was also used to evaluate how easily the masks could be cleaned again for use on a subsequent part in the restoration phase.

Does epoxy coating FDM masks before use improve mask stability and make mask cleaning easier?

Testing was completed in two separate runs of FDM masking samples on the same day in the same conditions. One set of samples was coated with epoxy BJB TC-1614, while the other was left as printed. This was applied to test if coating the mask would help with cleaning overspray off the mask between uses or improve mask longevity.

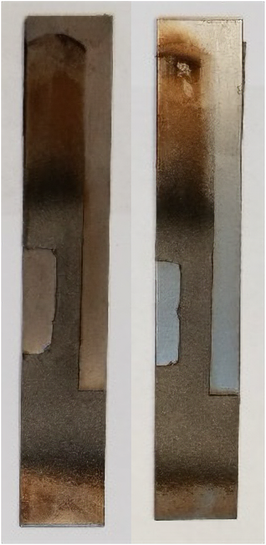

How does the masked edge of the coating on the tool steel samples appear after masks have been removed?

In order to establish if the FDM masks could produce a clean crisp edge for the TBC, the samples were visually inspected after the thermal spraying process. They were graded – A through F – based on the results achieved.

- A – Clean corners, no coating disruption, roughness<100µm

- B – Clean corners, no coating disruption, roughness<150µm

- C – Rounded corners, slight coating disruption, roughness<200µm

- D – Rounded corners, slight coating disruption, roughness>200µm

- F – Rounded corners, significant coating disruption, roughness>200µm

Do the FDM masks show any signs of warpage, change in flatness, or melting after the testing?

It was decided to measure this question qualitatively following the restoration phase. The same A-F grading system was used.

- A – No flatness change, no melting, no warping

- B – Slight change in flatness, no melting, no warping

- C – Slight warping and change in flatness, no melting

- D – Dramatic warping, change in flatness, slight melting

- F – Detrimental warping and melting

Thermal Exposure of the FDM Mask During the Process

Preliminary investigations of the selected thermal spray process and FDM test specimen revealed surface temperatures near 177°C (350 °F).

Stratasys ULTEM™ 1010 resin thermoplastic is a material with a glass transition temperature (Tg) of 215 °C (419 °F) and hardness of 109 (Rockwell M) and heat deflection temperature of 212 °C (413 °F), making it highly suitable for this application in both thermal stability and abrasion resistance. In fact, ULTEM™ 1010 resin has demonstrated extended use at these temperatures in composite tooling applications within an autoclave. Other FDM materials, depending on the process temperature, can be selected if requirements are lower. PC (polycarbonate) and Nylon 6 were both tested in this investigation and found not to be suitable for high-temperature TBC processes.

Thickness Variation of Masks Throughout the Testing

Before the process, coated masks were slightly thicker than uncoated masks due to the added thickness of the epoxy coating.

In-process, the uncoated masks showed a faster thickness increase due to more buildup and adherence of TBC than the epoxy coated masks, demonstrating the epoxy coating to be an advantage.

After the restoration phase, uncoated masks retained more TBC on the surface than the epoxy coated masks as the coating was easier to remove from the epoxy coated masks. The epoxy-coated masks also retained their original thickness slightly better due to the epoxy’s resistance to the grit blasting, again showing the epoxy coating to be an advantage.

Similar behavior can be seen in the masks’ weight change through the process.

While the uncoated samples before processing measured slightly lower roughness than the coated samples, the surface was generally smoother and shinier on the coated samples. However, imperfections such as bubbles inflated the roughness values on the coated samples.

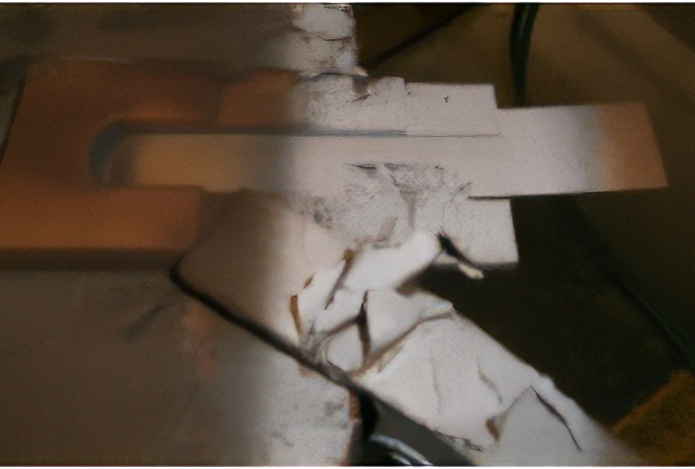

After the restoration phase, the surfaces were not 100% restored but in a reusable condition as the image below would indicate. The surface roughness measurements after restoration revealed a slight performance gain with the use of the epoxy coating.

Ultimately it was found that a built-up coating was much easier to remove from the epoxy coated masks during restoration. This also shows in the resulting thickness measurements after the thermal spraying process as the uncoated masks measured more build-up, revealing a performance boost with the epoxy coating.

Uncoated masks after the restoration phase averaged a step thickness of 4.978 mm (0.196 in.), which is a decrease of 0.127Â mm (0.005 in.) from grit blasting. Coated masks averaged 4.724 mm (0.186 in.), which is only a decrease of 0.076 mm (0.003 in.).

Design & Printing Recommendations

Based on this experience and testing, Stratasys recommends the following for designing and printing FDM masks for thermal spray coating.

Geometrical Considerations:

The mask should have a minimum thickness of 4.0 mm (0.16 in.). See the section on toolpath parameters for further details.

FDM Mask Material Selection:

As mentioned previously, ULTEM™ 1010 resin is the most suitable material currently offered due to its high thermal stability and low CTE. Depending on your chosen spray process parameters – particularly if there is a low maximum temperature, brief exposure, or a small number of parts to be coated – alternative FDM materials may be suitable, such as ULTEM™ 9085 resin.

Part Orientation:

FDM part behavior under load and thermal exposure can vary depending on print orientation. Parts should be orientated for toolpath generation and slicing such that the stiffest and most resistant plane is selected for the majority of the mask geometry. This helps reduce the warpage of the mask during the intense heat applied by the spraying process. If a mask produces unsatisfactory results, an alternative print direction is a sensible alternative to investigate.

Printer Toolpath Parameters:

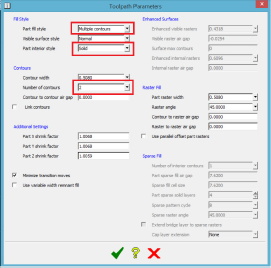

It is recommended to use the following parameter settings in Insight™ as highlighted in Figure 8.

Contours: Minimum of two. Contours help preserve a crisp edge on the mask and for most geometries provide a better fill ratio than solid raster infill alone. Customers may consider increasing the number of contours to potentially gain better results but should be aware this mode of printing is slightly slower than solid raster.

Interior Style: Part infill should be set to solid.

It is understood that using multiple contours and solid infill helps to provide a more stable and accurate edge on the mask and thus gives a crisper parting line between coated and uncoated areas. Solid or more massive parts will also take longer to heat up during the process and could be more thermally stable as a result.

Part Post Processing:

Coating FDM masks with a high temperature-resistant epoxy resin is highly recommended. As the experiment showed, both the dimensional stability and ease of cleaning were improved afterward in the restoration phase.

As an example, the BJB TC-1614 epoxy coating is capable of withstanding temperatures above 350 °F: It is a two-part epoxy that may be brushed on 3D printed parts as a surface coating or soaked into parts at an elevated temperature to help thin the epoxy so it can be used as an impregnation.

Conclusion

Based on dimensional stability and the lack of warping, ULTEM™ 1010 resin was selected as the optimal FDM material for thermal spray masking.

Based on the lack of coating adhesion and buildup on the FDM masks, the use of BJB epoxy coating provides increased performance that may result in longer useful life of FDM masks.

The information in the print settings recommendation section provides suitable guidance for any customer wishing to print their own FDM masks for TBC processes.