Stratasys Origin One vs EnvisionTEC and Carbon

Since the Stratasys acquisition of Origin in December of 2020, they have been working to relaunch Origin’s product under the Stratasys brand. The Stratasys Origin One is available for order now, shipping in Q4.

Programmable Photopolymerization

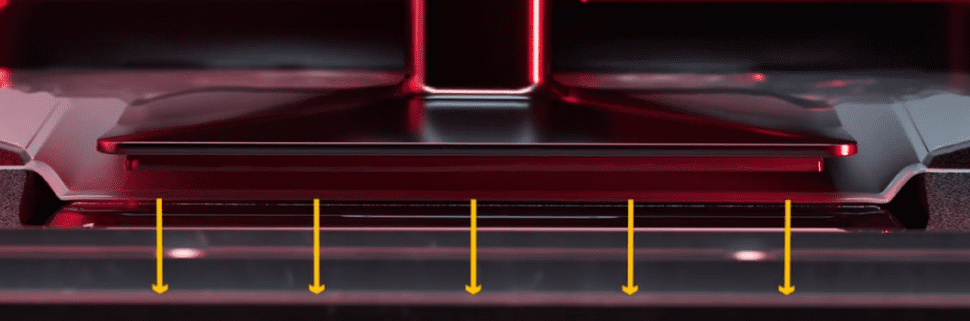

The technology that powers the Stratasys Origin One is called Programmable Photopolymerization or P3. It is a form of vat photopolymerization, specifically Digital Light Processing or DLP. Simply put, a vat of photopolymer resin is partially cured to a build platform with a high-resolution projector, layer by layer. A critical feature of DLP technology is the separation mechanism used to ensure parts do not stick during printing. P3 uses a pneumatic separation mechanism where the air is pumped underneath a membrane to slightly inflate it, allowing the cured layer to remove easily. This is one area that separates P3 and Origin from other DLP powered machines, such as those from EnvisionTec and Carbon.

Stratasys is no stranger to photopolymer resins. Their Polyjet product line has provided high detailed 3D printed parts in full color and a wide range of materials for many years. Polyjet jets microscopic layers of photopolymer resin which then is fully cured on each pass and layer. Due to multiple material channels, Polyjet can provide multi-color and multi-material parts in a variety of textures and finishes. Although the Origin cannot print multi-color or multi-material parts, where it beats Polyjet is in throughput, accuracy, and production-grade materials.

Origin One

The two main players with DLP machines that rival the Origin One from Stratasys are EnvisionTec and Carbon. Both companies have been in the DLP space for many years and have developed state-of-the-art additive manufacturing equipment. The focus of this blog will be to see how the machines from EnvisionTEC and Carbon stack up to the Origin One from Stratasys, and why it’s the best choice. First, here are the specs of the Origin One.

Stratasys Origin One

Build Envelope: 192 x 108 x 370 mm

Software: Origin One cloud-based, 1 year Autodesk Netfabb license

Materials: 385nm resins from Stratasys ecosystem material partners, fully unlocked license available

Separation Mechanism: P3 Pneumatic

Accuracy: +/- 0.001″ or 25μm

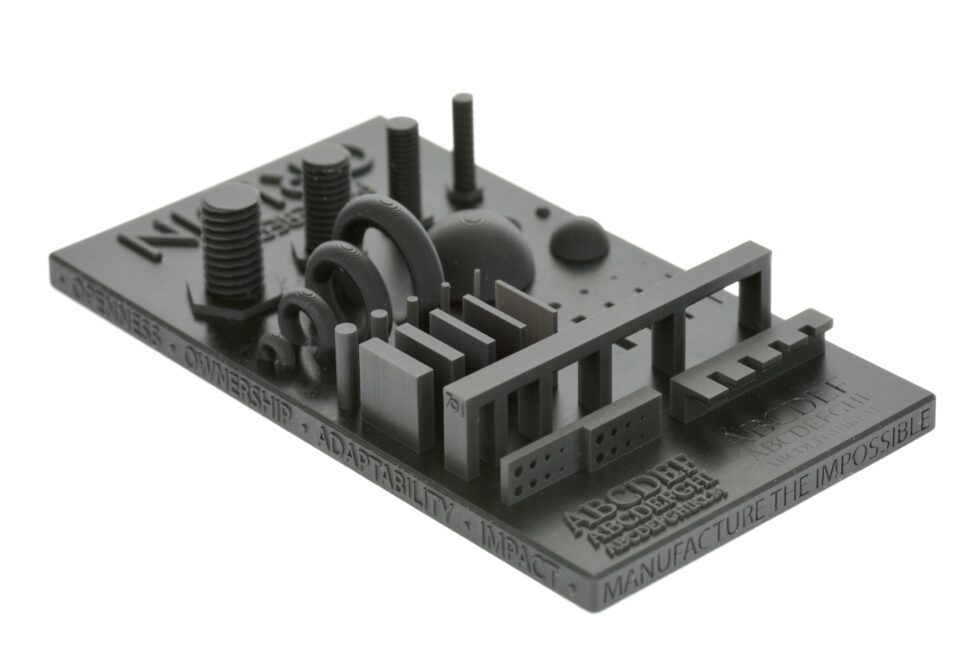

The Stratasys Origin One is a fully unlockable and programmable machine. It’s capable of printing a wide variety of parts from highly accurate, detailed parts with features as small as 50μm to large blocky parts encompassing the entire build area. The workflow starts with an Origin cloud-based web application where the print parameters are chosen. GrabCAD Print from Stratasys will be supported in 2022. The machine also comes with a one-year subscription to Autodesk Netfabb, for further job processing. After a print has finished, the parts are washed with isopropyl alcohol in a sonication bath. This process removes excess resin and cleans the parts prior to curing. After a few minutes of cleaning, the parts are placed in a UV cure box for 5-10 minutes, depending on part size and material selection.

Stratasys has partnered with major material suppliers such as Henkel, DSM, and BASF to develop and qualify materials for Origin One. Many of the Henkel materials were developed using the Origin One. Also available is a material development kit license that fully unlocks the machine for any 385nm resins.

EnvisionTec

There are two printers from EnvisionTec that compare to the Origin One. The Perfactory P4K Series and the Envision One cDLM Mechanical. Let’s start with the Perfactory P4K Series, of which there are four models.

EnvisionTec P4K

Models: P4K 35, 62, 75, or 90

Build Envelope:

90 x 56 x 180 mm (P4K 35)

160 x 100 x 180 mm (P4K 62)

192 x 120 x 180 mm (P4K 75)

230 x 143.75 x 180 mm (P4K90)

Software: Envision One RP

Materials: 385nm resins developed and sold by EnvisionTEC

Resolution: 35µm, 62µm, 75µm, or 90µm

Separation Mechanism: Mechanical tilting

EnvisionTEC has an extensive material portfolio that covers a wide range of engineering applications. The P4K is a mostly locked system. 3rd party materials cannot be used and materials must be purchased from EnvisionTEC. The system settings are also locked. When a new material is used, EnvisionTEC must send the build settings to the printer prior to starting the print. With small parts, the P4K is capable of high throughput, using a similar workflow to the Origin One. The mechanical tilting separation mechanism provides a good surface finish but results in a slower build rate than the Origin One.

The P4K is slightly more challenging to operate. It has a time-consuming, delicate leveling procedure that, if not perfect, can result in failed prints or variations in part quality across different areas of the tray. Like all of the DLP printers listed, the P4K can print parts with excellent surface finish and fine detail.

Envision One cDLM Mechanical

Build Envelope: 180 x 101 x 175 mm

Software: Envision One RP

Materials: 385nm resins developed and sold by EnvisionTEC

Resolution: 93 µm

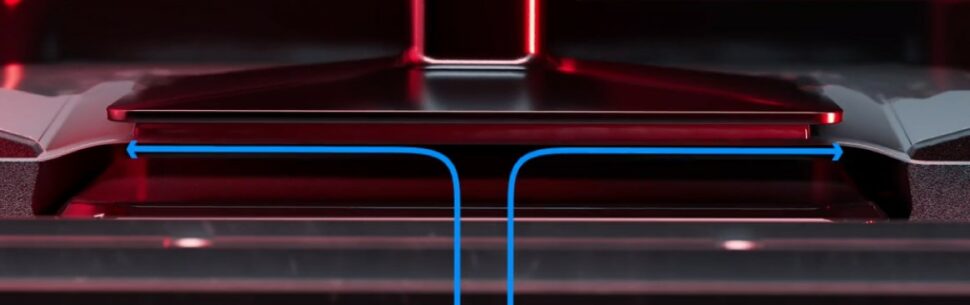

Separation Mechanism: Continous printing, oxygen dead zone

The Envision One cDLM Mechanical is very similar to the P4K but has some key differences. It offers slightly fewer materials than the P4K due to the different separation mechanisms. The cDLM Mechanical pumps oxygen under the resin vat which creates a “dead zone” from the oxygen and resin interaction. This allows the build platform to move continuously up in Z, resulting in faster print times. One downfall of this separation mechanism is that the oxygen causes the oxygen-permeable film to dent, resulting in a “dome effect”. This causes a visible variation across the build area which can lead to inaccurate parts. Furthermore, the presence of oxygen limits the types of chemistries that can be printed. The cDLM Mechanical has a similarly challenging leveling procedure to the P4K, and the system settings cannot be changed.

Carbon 3D

Carbon 3D has 2 DLP printers that compare to the Origin one. The Carbon M1 and M2. Since the only difference is the build volume, let’s look at the larger M2.

Carbon M2

Build Envelope: 189 x 118 x 326 mm

Software: Carbon software

Materials: Carbon developed resins, some 3rd party

Resolution: 75μm

Separation Mechanism: Oxygen dead zone

The Carbon M2 is a reliable system with good print-prep software and material selection. The system settings are locked and sent by Carbon, and although most of the materials must be purchased directly from Carbon, they are slowly adding 3rd party options. Most of Carbon’s high-performance materials are 2-part resins. Once the resins are mixed, they have a short pot life of 8-12 hours. After that, the material cannot be printed. This leads to high material waste, upwards of 100ml per build. The workflow is slightly different than the machines above, as most Carbon resins require a thermal post-cure for 8-12 hours, which means a much longer time to part.

The Carbon M2 purchasing model is “machine as a service”. Carbon replaces the machine every 3 years which means high uptime and reliability. However, since the machine is not owned by the user, and the Carbon materials are more expensive than 3rd party options, the M2 has a higher total cost of ownership than the Origin One. Similar to the Envision One cDLM Mechanical, the separation mechanism in the M2 is an oxygen dead zone. Apart from limiting the types of chemistries that can be printed, this separation mechanism reduces the part quality on fine details, it makes printing large cross-sections virtually impossible, and it results in delicate green state parts prior to curing. Overall the Carbon M2 is a powerful machine, but the locked system settings, restricted material selection, and expensive cost of ownership make the Origin One a better choice.

The Origin One has everything you would want out of a DLP 3D printer. It has fully programmable print settings, best in class dimensional accuracy, throughput, and part quality, and an open material selection. The parts are very strong in the green state prior to curing, which makes the workflow easy and scalable. Furthermore, now that Origin One is under the Stratasys brand, it comes with the infrastructure and support that has been a cornerstone of Stratasys since its inception. DLP technology is bringing the additive manufacturing industry into end-use applications by challenging traditional manufacturing methods. With ever-changing supply chains and logistical problems, businesses are seeking in-house solutions that provide them with the flexibility, throughput, and quality they need. There’s only one DLP machine that accomplishes that, the Stratasys Origin One.