Stratasys F3300 - The Next Generation of FDM

We pay very close attention to the Additive Manufacturing industry here at CADimensions and have been overwhelmed with all the new and innovative technologies emerging. It seems as if there is a new 3D printer or technology being released every month, but we are excited to see Additive become more accessible and widely adopted across all industries. The industry is certainly trending towards highly loaded resins and advanced composite powders for end-use applications, but there is one technology that has stood the test of time and is still the most widely used Additive technology: FDM. Fused Deposition Modeling remains at the top of the list for any Additive portfolio due to its simplicity, availability, and continuous improvement. One of the early advancements in FDM technology was the implementation of two dedicated printing nozzles. This enabled the printing of two materials, most commonly a model and a support material. If you’ve been watching the industry like we have, you know there is another new advancement happening in FDM, that being automatic tool changing technology. We’ve seen this more recently in hobby or prosumer level FDM 3D printers, but we have yet to see it implemented at an industrial scale, until now. Introducing the Stratasys F3300, the next generation of FDM® technology from the world leader in industrial Additive.

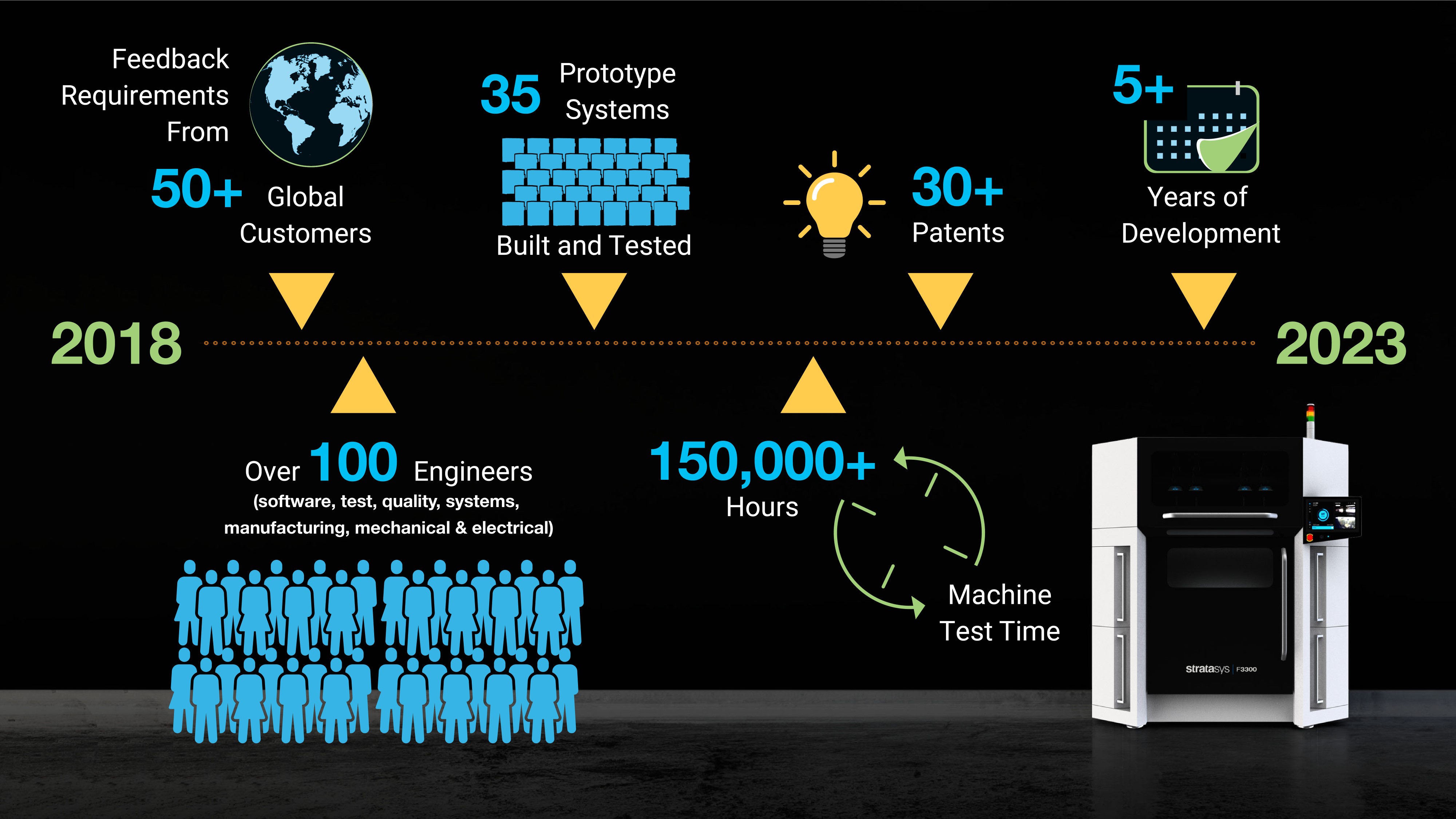

The F3300 is a long-awaited advancement from the inventors of FDM. They’ve been hard at work developing this machine since 2018 with feedback from over 50 global customers with over 100 engineers building and testing 35 prototype systems. Additionally, Stratasys has 30+ patents on this technology and over 150,000 machine test time. They are finally ready to release it to the world, and here is everything we know about the F3300.

The F3300 was designed to move FDM forward. It enables game-changing throughput, best-in-class uptime, and a lower cost per part. This machine is built for manufacturing. It has an up to 2x faster time-to-part compared to leading industrial filament printers. The build volume is large at 600mm x 600mm x 800mm (23.6 in. x 23.6 in. x 31.5 in.) The gantry speed is increased as well as faster extrusion rates – up to 270 cc/hr. Advancements also include linear motors and encoders for fast, precise extruder movement. The F3300 is capable of 500mm/s printing, 1500mm/s non-printing, with a 1.2 G acceleration. This is the fastest Stratasys printer to date.

Four Smart Extruders

The F3300 has four independent extruders which allow for mixing and matching of materials based on job requirements, enabling unprecedented redundancy. If an extruder clogs or jams, a fresh extruder is ready to be picked up and dropped in for continuous printing. With four extruders, the time to switch from model to support material has been reduced from 60 to 15 seconds. These extruders are preloaded on a rack to warmup and cooldown without affecting part build time, resulting in overall less non-print time. The four extruders also enable multi-resolution and multicolor prints. Without multiple extruders, a multi-color print would require the printer to be paused, loaded with a secondary color, then resumed. Even then this would only allow for multiple colors across different layers. The F3300 is capable of multiple colors within a single layer. Operator time is also kept to a minimum as all the extruders are calibrated automatically with a true autocalibration system. Each extruder has a load cell to monitor the pressure, and dual TC control for advanced melt flow of filament.

The extruders start with the tool base, which are fixed to the system and contain a material cutter. The hot end, or nozzle, connects to the drive end which lives in the tool base when not printing. When the F3300 switches the tool base, it places the current drive end with connected nozzle back into the tool base and picks up the next drive end. This is approximately a 15 second process. The machine also has easy access front loading spools and extruders with simple connections.

The oven design has also been revamped with a patented modular thermal control for consistent repeatable part quality at a wide range of temperatures up to 220°C

Materials

Four of the most used FDM materials will be available at launch: ASA, PC, ULTEM™ 9085 Resin, and Nylon 12CF. These materials are wound on a newly designed spool with 4100cc (250ci) of material on each spool to reduce spool changes. More importantly, there is an integrated material dryer on the F3300 with a 120C capacity. This will ensure that all the loaded materials are kept at an optimal temperature and humidity. Dryer material means better part quality. Additionally, Stratasys has an extensive roadmap for performance materials to be released as the machine matures, to include the Stratasys portfolio with the Antero family.

Advanced Control System and Software

A faster printer with automatic tool changing technology and onboard material dryers is great, but means nothing without the right control software. The F3300 has an advanced control system for real-time health monitoring of the machine. The reliability of the machine starts with these monitoring capabilities and mechanical design focused on maximum uptime and repeatability. Furthermore, traceability is built right into the components which means this printer will be ready for the necessary certifications required for the most demanding industries. There is an intuitive 15.6” user interface monitor with two cameras displaying both a front extruder view, and full chamber view. It comes stock with MTConnect and 428 data streams. The extensive numbers of sensors and data enables predictive maintenance, part quality validation, and machine learning for correction in situ.

The F3300 comes with the user-friendly GrabCAD Print slicing software for preparing builds, and the more advanced Insight software for precise toolpath control. Also available is the newly released GrabCAD Print Pro slicing software. This enhanced version of GrabCAD Print offers valuable tools such as accuracy center, to modify print files and achieve the most demanding tolerance and dimension requirements, per part material estimation to fast track material costs, and manufacturing templates, which allows multiple users to work of the same validated settings ensuring consistent results.

Who is the F3300 for?

While the F3300 would certainly be a killer prototyping machine, the true value extends far beyond prototyping. This printer is for production managers, manufacturing engineers, shop managers, and AM leaders alike who need to create reliable, repeatable, and accurate jigs, multi-material or multi-resolution fixtures, and low volume production or spare parts in high performance materials, at a lower cost. Here are a few industries where the F3300 is destined to make a difference.

Aerospace/Defense/Space

Low volume production parts, light weighting- Jigs, fixtures, & manufacturing support tools

- Spare parts for older planes

Automotive/Rail

High volume prototyping- Racing parts

- Surrogate parts for testing lines

Service Bureaus and AM Labs

High volume prototyping- Low run production

- Faster printing and faster material change over

Key Differentiators

Low FDM Cost Per Part

High throughput & High part yield- Lower material pricing

- Easy operation & Reduced labor

Industry Leading FDM Part Quality

Leading accuracy & repeatability- Multi-resolution & Multi-color parts

- Dry material & Strength improvements

Design for Manufacturing

Traceability & Reliability- Security & Connectivity

- Increased Uptime

High-Level Details

- Build Volume: 600mm x 600mm x 800mm (23.6 in. x 23.6 in. x 31.5 in.)

- Fully heated chamber with variable speed fans

- Four dedicated multizone extruders with automatic tool changing

- Automatic calibration

- Four on-board material dryers up to 120C

- Large 4100cc (250ci) spools

- ASA, PC, ULTEM 9085, and Nylon 12CF at launch

- Full-color touch screen display with quick status screens

- Predictive failure indicators with machine learning

- Software: GrabCAD Print, GrabCAD Print Pro, Insight

- Achievable accuracy: +/- .067 mm or +/- .0015 mm per mm, whichever is greater (+/- .0026 in. or +/-.0015 in. per in., whichever is greater). Z part accuracy includes an additional tolerance of -0.000/+ slice height

Click here to view the full spec sheet!

We’ve been patiently waiting for this new advancement in FDM with the F3300, and could not be more excited to start having further conversations with you! Automatic tool-changing technology with Stratasys is finally here, making what’s possible with FDM even more endless. Join us on March 21, 2023 as we host a webinar to dive even further into the F3300. Click here to register!