3D Printing in Education: Practical Lessons That Inspire Students to Create

3D printing helps students learn design, iteration, and problem solving with real parts. Schools add printers to labs and classrooms, then align projects to standards. Start small. Use safe materials. Build repeatable projects. Grow the lab as demand rises.

3D printing turns ideas into parts that students can hold, test, and improve. It supports STEM, CTE, and design programs. When schools add a few reliable printers and a simple workflow, teachers get hands-on lessons without extra chaos.

Jump to a section

Why 3D printing belongs in classrooms

Skills students build with 3D printing

Where 3D printing fits in the curriculum

How to choose printers and materials

Simple classroom workflow and safety

How to scale a lab on a budget

Project ideas students love

3D printing vs traditional school fabrication

Common challenges and how to avoid them

How schools fund 3D printing programs

Common questions

Why 3D printing belongs in classrooms

Quick answer. It connects theory to practice. Students design, print, test, and improve. They see how constraints shape real products.

Hands-on work makes abstract topics stick. A print that clicks or snaps in builds confidence. Failure becomes a lesson. Teachers can tie each print to standards and rubrics so results are clear.

Skills students build with 3D printing

Quick answer. Students learn CAD, tolerances, iteration, and communication. They also learn safety and lab care.

- Design literacy. Sketch, model, and prepare files for print.

- Tolerances and fit. Parts must align, move, or fasten cleanly.

- Iteration. Change one thing. Test again. Keep notes.

- Teamwork. Share files, track versions, and divide roles.

- Lab habits. Safety first. Clean tools. Clear logs.

Where 3D printing fits in the curriculum

Quick answer. Use it in STEM, engineering, art, and CTE. Aim for short projects that map to standards and skills.

Schools place 3D printing in makerspaces, engineering electives, and capstone courses. Many teachers pair it with coding or simple electronics. The best projects have a clear prompt, a short print time, and a rubric that rewards process and outcome.

How to choose printers and materials

Quick answer. Pick reliable printers that are safe for classrooms and easy to service. Start with a common material like PLA. Add specialty options later.

- Reliability. Enclosed builds, auto bed leveling, clear error prompts.

- Ease of use. Simple slicer profiles and quick swap nozzles save class time.

- Safety. Filtered or enclosed systems help in small rooms. Follow local policies.

- Materials. PLA for most lessons. Add PETG or tough materials for functional parts.

- Support. Classroom training and quick service keep labs running.

Tip. Standardize on one or two printer models. Shared spares and the same slicer profile reduce errors.

Simple classroom workflow and safety

Quick answer. Use a short queue. Review files. Start prints early. Keep a clean handoff at the end of class. Log each job.

- Students submit STL files with part name and time estimate.

- Teacher or lab aide checks orientation, supports, and time.

- Start prints during planning periods. Use overnight for long jobs.

- Students label parts and record results with photos and notes.

- Reset the lab. Store materials. Clear the queue.

Follow local safety rules and MSDS guidance. Ventilation and PPE may be required for some materials and processes.

How to scale a lab on a budget

Quick answer. Use a pod of three to five printers. Add another pod when the queue grows. Track usage and costs per class.

- Pods. Group printers so one adult can manage the set.

- Spare parts. Keep nozzles, beds, and feeders on hand.

- Funding. Tie purchases to standards, enrollment, and outcomes.

- Service plan. A support contract protects the school calendar.

Project ideas students love

Quick answer. Choose projects that print in under two hours and teach one key skill.

- Parametric phone stands. Teaches angles, fillets, and fit.

- Snap-fit boxes. Teaches tolerances and lid clearances.

- Gears and simple machines. Teaches ratios and motion.

- Art and texture tiles. Teaches relief and pattern.

Assessment. Grade on design intent, print readiness, iteration notes, and a short reflection.

3D printing vs traditional school fabrication

How does 3D printing compare to laser cutting or shop tools?

3D printing excels at complex shapes, internal channels, and quick iteration. Laser cutting is fast for flat parts. Shop tools are best for structural materials and finishing. Many schools combine them for the best mix of speed, safety, and capability.

Common challenges and how to avoid them

What slows classrooms down and how do we fix it?

Queues grow when prints take too long or profiles are inconsistent. Limit print times, standardize presets, and train student techs. CADimensions helps schools set repeatable workflows that fit real class schedules.

How schools fund 3D printing programs

How do we justify and fund a lab upgrade?

Schools use grant programs, Perkins V funds, and departmental budgets. CADimensions works with educators to scope needs, select equipment, and align purchases to standards and measurable outcomes. Formlabs offers education pricing on printers and materials to help programs scale.

How CADimensions helps. We set up school labs, train staff, and support printers through the year. We also help align projects to standards and budgets so teachers can focus on teaching.

Need help starting or scaling a lab? Explore our education services.

Common questions

What is the best 3D printer for a school lab?

Pick a reliable, enclosed system with strong support and simple slicer presets. Standardize the model across the lab.

Which materials are safe for classrooms?

PLA works for most lessons. Use PETG or similar materials for stronger parts. Follow local safety rules for storage and ventilation.

How do we prevent long print queues?

Limit projects to short prints, run jobs overnight, and add a second printer pod when queues grow.

Do students need CAD before they print?

Basic CAD helps, but you can start with templates and simple edits. Build CAD depth across the term.

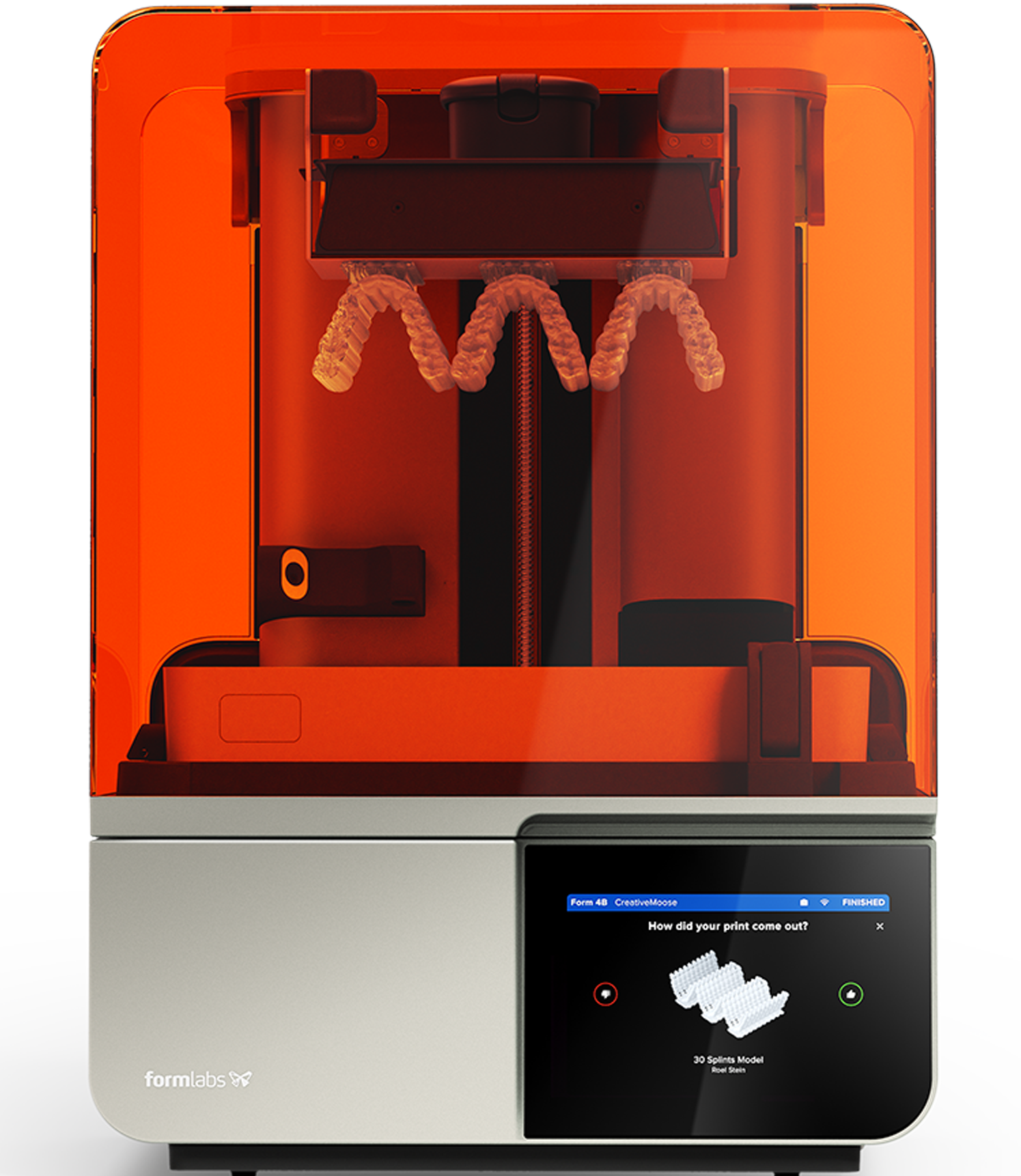

Bring Formlabs to Your Classroom

Formlabs printers help schools introduce advanced manufacturing at a manageable scale. Students learn professional workflows on the same technology used in industry, without a steep learning curve.

- Safe and reliable. Enclosed resin systems designed for education.

- Curriculum-ready. Lesson materials align to STEM and CTE standards.

- Industry relevant. Teaches additive processes, materials, and design for manufacturing.

About CADimensions

CADimensions helps schools and universities build hands-on design programs with reliable 3D printing labs, training, and support. Learn more at CADimensions.com.