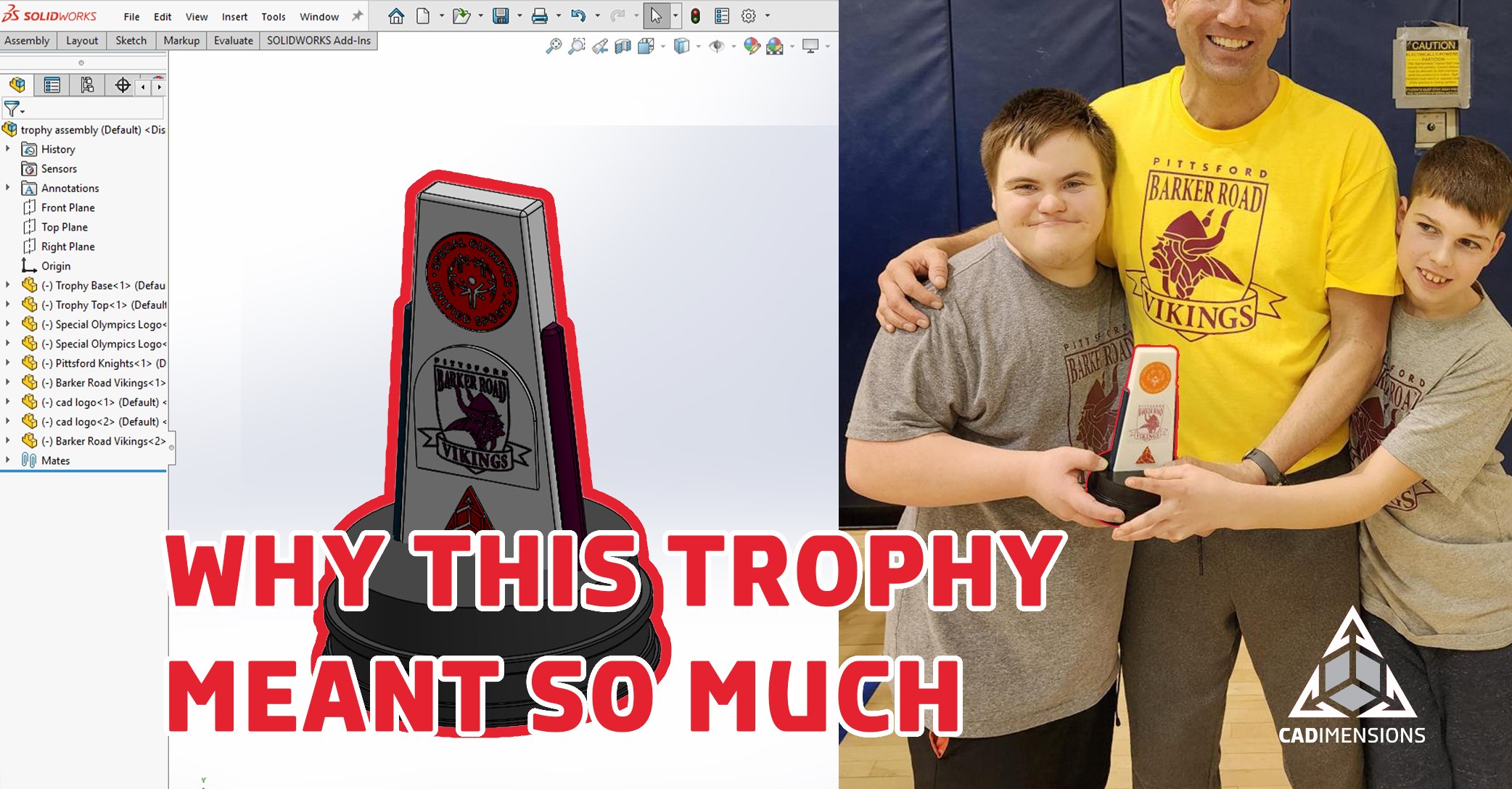

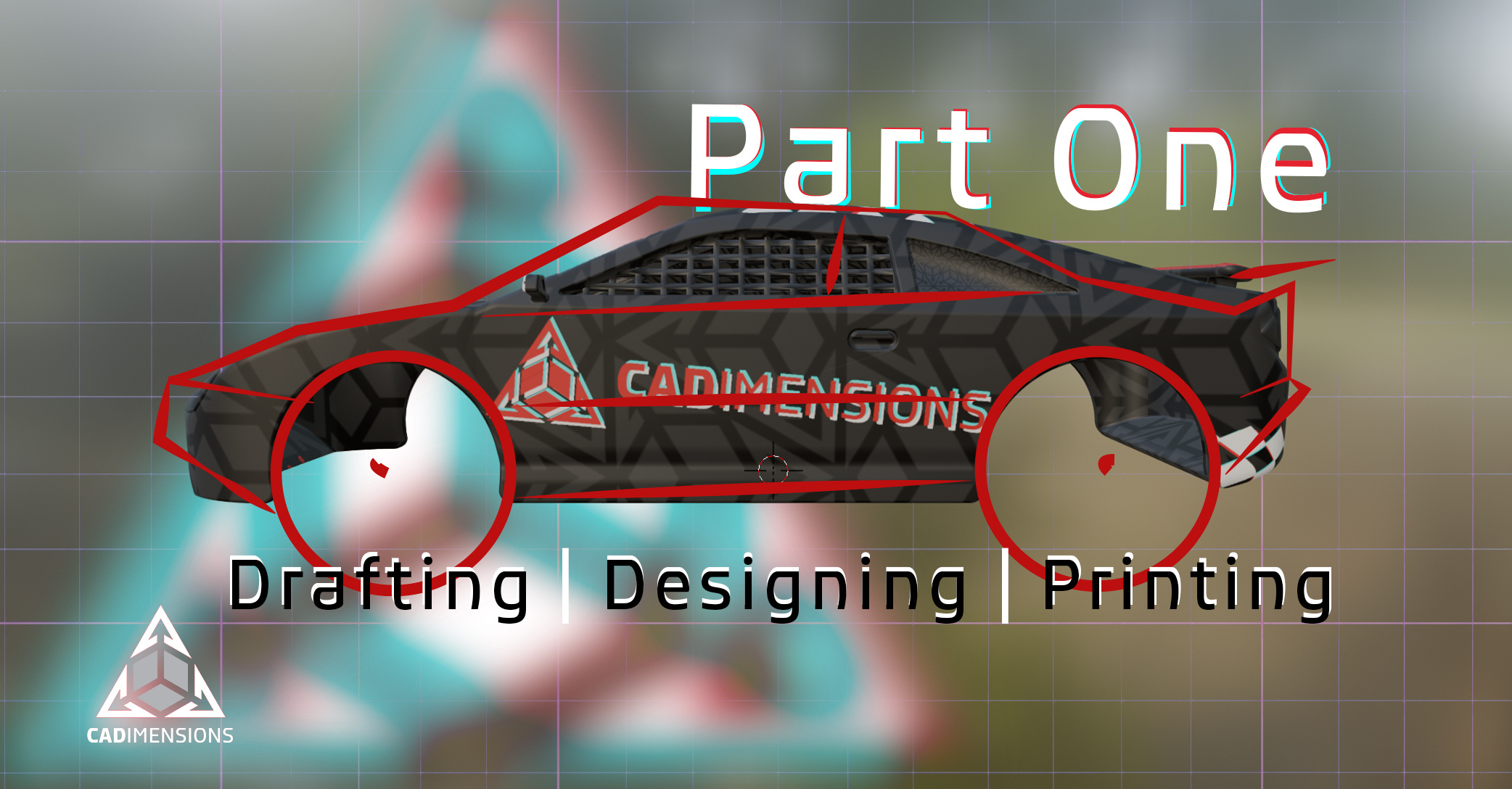

Part 1 – From Imagination to Exhibition: Designing and 3D Printing a Model Car for the MOST Museum in Syracuse, NY

As part of the CADimensions' donation to the Museum of Science and Technology (MOST) in Syracuse, NY, our team collaborated to develop an idea that showcases the broader impact of our work as an engineering and 3D printing service provider and reseller to young minds. This sparked the idea to visually translate the journey from a basic sketch to a physical model of a car.

Step 1 – Idea to Napkin Sketch

The napkin sketch was more than just a drawing; it represented a project Ben Davis, our Marketing Strategist had long envisioned completing during his career at CADimensions, and this opportunity was the perfect opportunity to bring it to life. His sketch laid the groundwork for the entire project. It provided a starting point for discussions and brainstorming sessions, allowing the team to visualize and refine the concept. Ben’s ability to translate an idea into a visual form, even in its most rudimentary state, demonstrated the importance of creativity and quick thinking in the early stages of design.

Step 2 – Presenting the Concept to the MOST

Presenting the napkin sketch to the team and the MOST Museum was the second major milestone. It ignited excitement and interest, setting the stage for the collaborative efforts that would follow. This idea illustrated the potential of the project and acted as a catalyst for the detailed planning and execution that lay ahead.

Step 3 – Getting the Right Team Members Involved

Ensuring the success of the model car project for the MOST required assembling a talented and dedicated team, led by Ben Davis, who recruited individuals based on their unique expertise. Sara Reynolds, the Service Team Manager, helped oversee the project and kept the team on schedule alongside Ben. Cam Murray integrated the 3DEXPERIENCE platform for seamless remote collaboration. Amy Peterson designed the car shell, merging form and function. Autumn Dekay focused on the internal design, including the chassis, wheels, tires, and electronics. Matt Corcoran handled all things additive manufacturing – from material and machine selection, to testing and then the final print. Each member’s contributions were vital in transforming the initial concept into a functional, visually stunning model car, exemplifying the power of teamwork and innovation.

Step 4 – Leveraging the 3DEXPERIENCE Platform for Enhanced Remote Collaboration

At CADimensions, most of our team is fully remote, with members spread across the country from New York to Colorado. To facilitate seamless cross-collaboration, we brought in Cam Murray, one of our Cloud Customer Success Advocate, to set up the necessary infrastructure. This allowed multiple individuals to work on a single file simultaneously and transfer files with ease. We also held numerous team meetings to review file progress, making this use of the 3DEXPERIENCE platform a game changer for us.

Step 5 – Designing the Shape of the Car Shell

Amy Peterson, our Product Designer was tasked with designing the shape of the car shell, a job that required balancing aesthetics, functionality, environmental considerations, and ergonomics. She needed to understand scale to ensure all components would fit together seamlessly once complete. Amy also worked closely with the Sr. Additive Manufacturing Application Engineer, Matt Corcoran to discuss materials and ensure the parts would print well, blending beauty with practicality in her design.

.png?width=1097&height=703&name=MicrosoftTeams-image%20(59).png)

Step 6 – Engineering the Mechanics of the Car

Autumn Dekay, one of our Technical Support Application Engineers meticulously designed the interior of the model car to ensure optimal functionality. She focused on the chassis, wheels, tires, and electronic placement, integrating each component seamlessly to achieve a robust and efficient internal structure. Her work involved careful consideration of mechanical design principles and engineering precision, ensuring that every part not only fit together perfectly but also performed its intended function effectively. Throughout this process, Autumn would occasionally run her work by peers such as Fred Compton, our Sr. Technical Support Application Engineer for another set of eyes and additional considerations. This step is crucial to transforming the car from a concept into a fully operational model.

Step 7 – Painting the Exterior Car Design in Blender

Ben Davis was in charge of the how the exterior of the car looked. He began by hand-drawing the graphics, ensuring that every detail was carefully crafted to reflect the vision for the model car. These hand-drawn graphics were then imported into Adobe Illustrator, where Ben refined and digitized them, enhancing their precision and quality. After perfecting the design in Illustrator, he brought the graphics into Blender. In Blender, Ben applied the graphics to the car model, carefully adjusting colors and textures to create a visually appealing exterior. This process allowed Ben to transform his initial sketches into a stunning, lifelike representation of the model car, showcasing his artistic skills and attention to detail.

Step 8 – Additive Manufacturing Machine and Material Selection

In collaboration with Matt Corcoran, our work involves selecting appropriate machines and materials for each component of the car design. Throughout the design phase, Matts role entails close coordination with design engineers – like Amy, Autumn and Ben in this instance due to the Blender design, to guarantee their creations are printable. This involves navigating through various materials and technologies, each offering unique aesthetics and tactile qualities that influence the final product's appearance and feel.

Step 9 – GrabCAD, Testing and Analyzing Sample 3D Prints

Once the Blender design phase is complete, Matt harnesses GrabCAD to initiate the next stage of our process which and begins by sending the designed files for test printing. A key aspect of Matt's role is facilitating communication between the design and tech teams. He works closely with engineers to address any issues that arise during the printing process, such as optimizing the placement and strength of various features. This approach ensures that each prototype iteration enhances the design's functionality and manufacturability, ultimately leading to a more refined and robust final product. Once perfected, we’re ready for the final print!

.jpeg?width=4032&height=3024&name=Image%20(13).jpeg)

|

|

To be continued…

We'll also be releasing a Part 2 of this blog that will detail the entire story from start to finish, so stay tuned for that!

.jpeg)