Challenges An Industrial Designer Faces & How to Avoid Them

What Exactly is Industrial Design?

Sometimes when people hear “Industrial Design,” they might not exactly know what it entails. With the word “industrial” in the title, they might imagine it deals with solely manufacturing, but that is not the case. Industrial design is the creative act of exploring and defining the form and function of a product, which comes before the production and manufacturing of the product. Industrial designers typically focus on the functionality, aesthetics, and manufacturability of a product. They uncover ways to make a product novel, add value, and consider things like ergonomics and how to make an overall better product for all parties involved.

The process of designing a product doesn’t come without its challenges. There are usually multiple design iterations, and the process from start to finish isn’t usually a straight line. As someone who has worked in the field, I would like to share some of the challenges I have come across in this process, and ways that you can overcome or alleviate them.

Some Challenges Industrial Designers Face

One of the challenges I have come across is transcribing what the customer/client wants, and being able to make their vision “come to life.” Sometimes they might provide you with napkin sketches of what the form should like, or a rough initial prototype. One of the next steps is taking this information, and creating a 3D CAD model. This model can then be used for design refinement, as well as a basis for creating prototypes and manufacturing drawings. Luckily, SOLIDWORKS has an arsenal of tools to help make this process easier.

If you have sketches or images to work with, you can use them as something known as a Sketch Picture. Sketch Pictures can be inserted into a sketch, and allows you basically trace over an image. This can help you accurately convey the form that way portrayed in the image. If there is a physical model that the design is based on, you can take images from different angles, and place them on unique planes to better represent the different sides of a product. It is always a good idea to test the form and function of a product to make sure it has good ergonomics. This is especially important when creating products that require human interaction. 3D Printing has made this easier, and testing the product early on by prototyping it can save a lot of headaches later on.

Learn Some New Techniques

Another recommendation for building complex models is to explore the mass amount of tools SOLIDWORKS has to offer. Making a model that is organic in form or has a rough spot that needs attention? Check out the Surfacing tools! You can create some really intricate forms by going beyond your basic boss & cut extrudes. Overwhelmed by the amount of tools and not understanding how to use them? Maybe we can help! We offer different training classes that cover advanced topics like Surfacing, Sheet Metal, and Simulation. We also have SOLIDWORKS Essentials, which is great if you are new to SOLIDWORKS or want a refresher to learn some great tips and tricks like the one mentioned below.

Replace Entity Tool

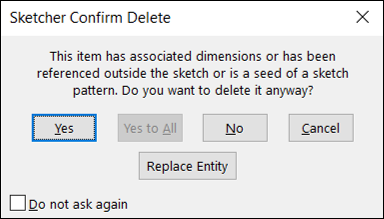

Another challenge industrial designers face is making changes to a model in SOLIDWORKS, and having the said change “break” other aspects or features in your model. If you have ever needed to make a modification to a feature, especially one that is higher up in your FeatureTree, this one is for you. One tool that you might not know about, is the “Replace Sketch Entity” tool. Replace Sketch Entity is a tool used to replace a single entity with another in an existing sketch while maintaining downstream references linked to that geometry. If you delete an entity with outside references, the Sketch Confirm Delete dialog will be prompted, and you can choose the option to replace it. It is also available under Sketch Tools> Replace Entity. It can save you from having to reattach relations manually, and can be a great way to make modifications without downstream consequences.

Collaboration with 3DEXPERIENCE

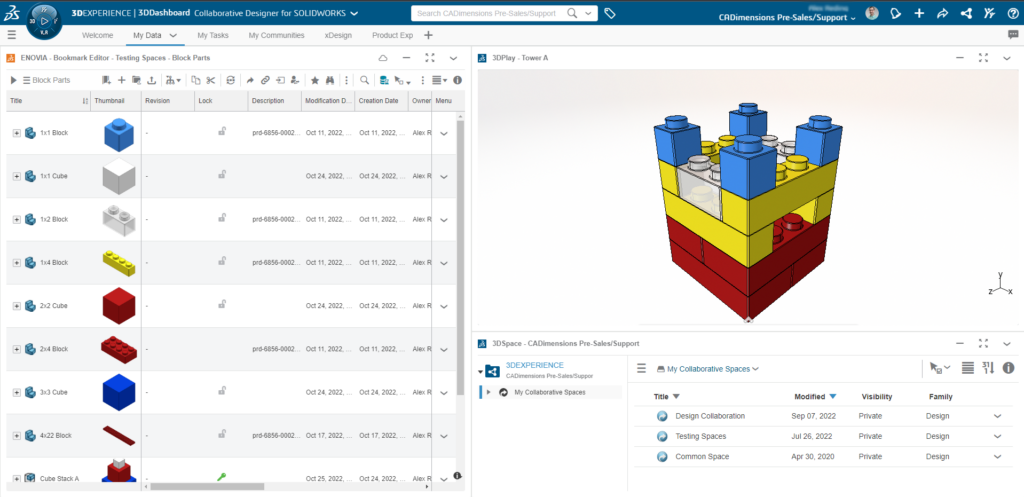

As an Industrial Designer, one of the biggest hurdles to jump is collaborating with engineers, other designers, and our clients. Sometimes both parties think they are on the same page, and then after hours of work are done, the client comes back, and says “that isn’t exactly what I had in mind.” To avoid this, a recommendation would be to set up your project in phases, so that there is frequent communication. 3D PDFs are a great way to share content, especially with those who might not have CAD software. Showing updates and changes through presentations are a great way to document and record the milestones along the development process.

Another tool that you can use is the 3DEXPERIENCE platform. The 3DExperience Platform with SOLIDWORKS checks all of these boxes, and more, by creating a collaborative platform that can be used to share files, manage projects and tasks, and allow designs to be stored securely on the cloud. Even with the basics of the platform, saving and working off files directly on the cloud allows teams to work on the same project without creating duplicates and stepping on anyone’s toes. Lastly, the biggest draw of all; while SOLIDWORKS runs on your local PC, the platform is browser-based. This means you can share content, revise designs, and create a strategy from any internet-connected device with extreme flexibility. To learn more about the 3DExperience Platform click here.

Ready… Set… Design!

If you have upcoming projects, give some of these tips and tricks a try. Or if you and/or your business are overwhelmed or want a fresh perspective, take a look at CADimensions Design Services. We can help you create or refine your designs. From modeling to creating drawings and marketing material, we’re with you every step of the way ensuring your success!