SAF Technology: Enhancing Precision and Productivity

In the ever-evolving world of manufacturing, technology milestones continue to redefine the way we design, prototype, and produce goods. One such groundbreaking innovation is Stratasys powder-bed fusion printing technology – Selective Absorption Fusion (SAF). SAF is gaining significant attention for its ability to refine precision and productivity in various industries. Let’s dive into the remarkable benefits of SAF technology and its transformative impact on additive manufacturing.

Understanding SAF Technology

How does SAF work? “Selective Absorption Fusion (SAF™) 3d printing is a polymer powder bed fusion process that uses industrial-grade piezo-electric printheads that jet high absorption fluid (HAF) onto a powder bed to define the area in which to form the 3d-printed object.

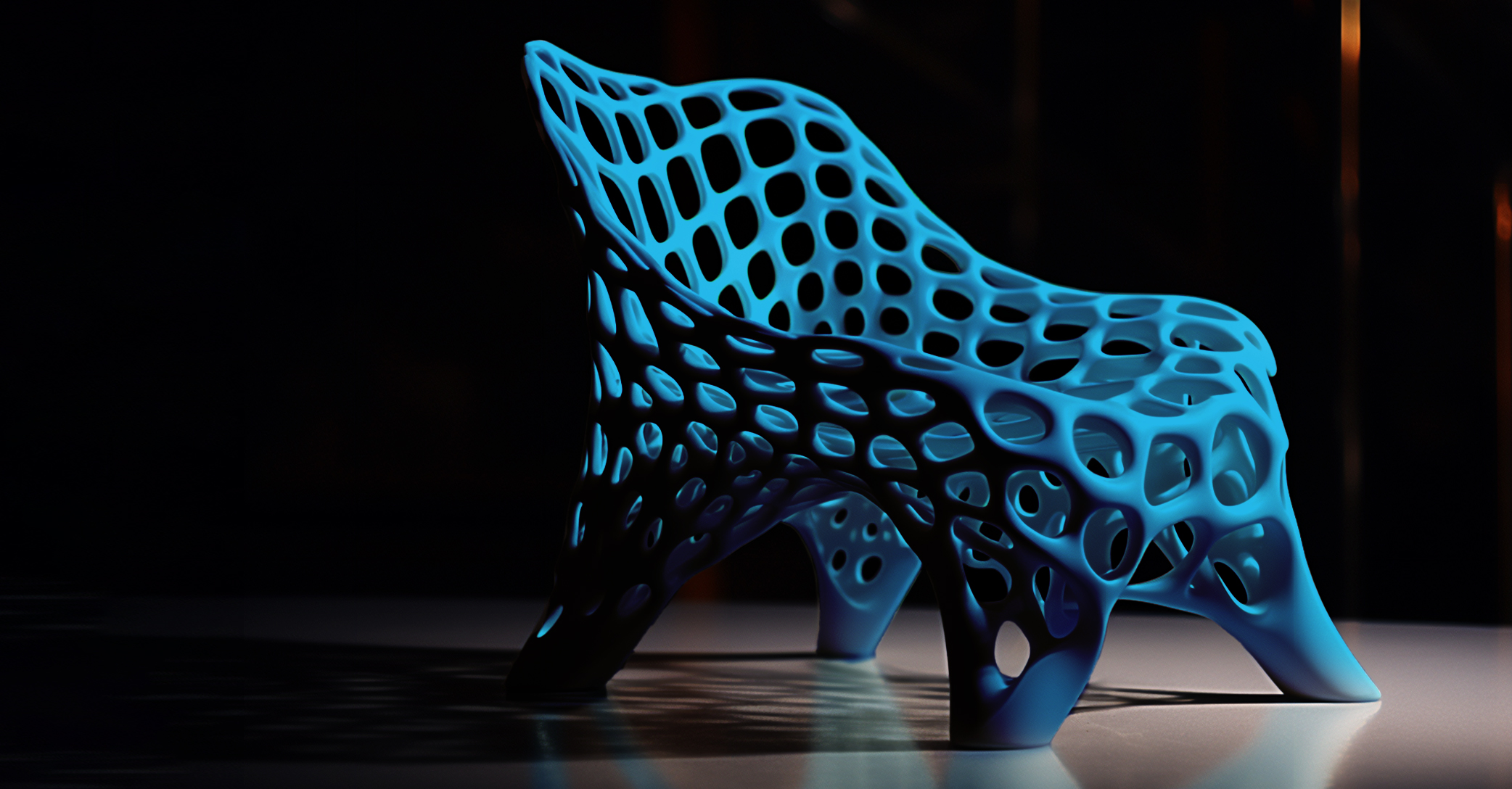

Design Freedom and Innovation

Through the power of SAF technology, parts that were once challenging or impossible to achieve using traditional manufacturing methods, are now obtainable. This design freedom empowers engineers and designers to push the boundaries of what is possible, unlocking their creativity and enabling the production of highly customized and unique components.

Automation and Increased Productivity

The reusable aspect of SAF material reduces waste and enhances productivity, as components can be manufactured with high repeatability and consistency. This allows manufacturers to optimize their operations, achieve faster time-to-market, and meet the demands of high-volume production while maintaining exceptional quality standards.

Industry Applications of SAF Technology

Selective Absorption Fusion has found diverse and extensive applications across industries. In the aerospace and automotive sectors, SAF permits the production of lightweight, durable components with intricate geometries, improving fuel efficiency and performance. In healthcare, SAF facilitates the creation of personalized medical models and prosthetics, tailored to individual patients' needs. The consumer goods industry benefits from SAF's ability to produce complex and customizable products, enriching design flexibility and market competitiveness.

Looking Ahead – New Era of Manufacturing Continues

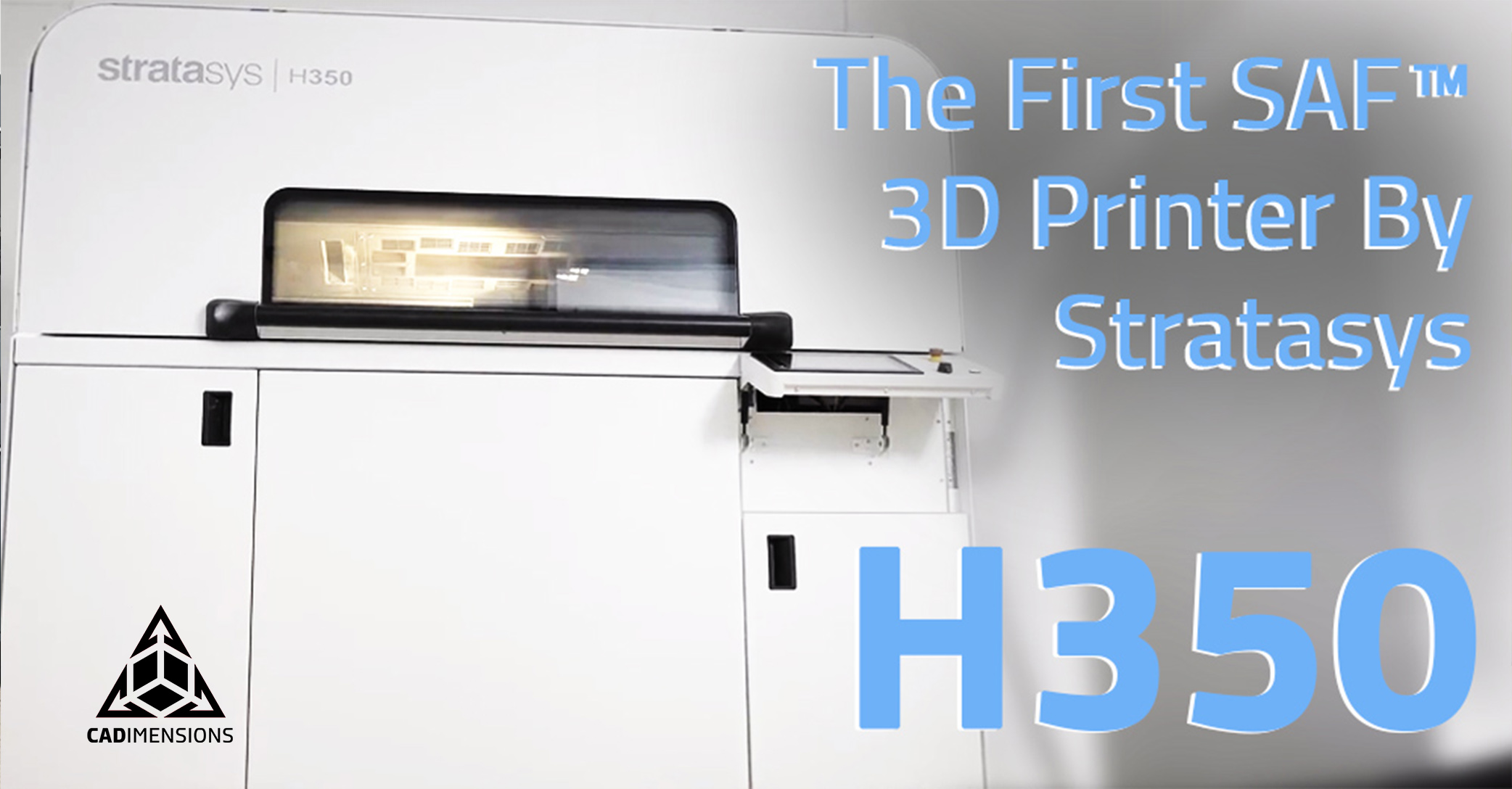

SAF technology powered by the H350 3D printer from Stratasys is revolutionizing the manufacturing realm by enhancing precision and productivity. Its ability to deliver design flexibility, and accelerated production times makes it a pivotal solution in the additive manufacturing space. As more companies adopt SAF technology, we can expect further advancements, expanded applications, and a new era of manufacturing excellence.