3 Reasons Metal Prototyping Today Isn’t Working

People have been making things for a long time. As the Industrial Revolution progressed, the status quo for manufacturing and metal prototyping became subtractive manufacturing. Like the common three-axis mills and lathes, these machines can be manually operated or driven by computer systems and motors. Though simple in function, these cutting tools have shaped the world we live in today. But times are changing and subtractive manufacturing is now failing to meet demands. Businesses that suffer from long lead times and slow product development are desperate to find new ways to make parts quickly. If you are an engineer and send a metal prototype part to your internal machine shop, chances are it will be 4-12 weeks before you hold that part in your hands. If you need it any faster, you probably have to bribe somebody with donuts. How do I know?

In my role as an Applications Engineer, I have the opportunity to visit businesses on a regular basis. They are often unhappy with their current processes and are investigating 3D printing as a potential solution. By far, metal prototyping is the biggest area companies are looking at to make parts cheaper and faster. Waiting a quarter of a year for a prototype part is absurd, and pales in comparison to the most efficient businesses I talk to. They turn around prototype parts within a week or so. From countless meetings and a lot of research, I’ve put together three of the most common reasons businesses struggle to make metal prototype parts fast.

1. Skilled Machinists are Hard to Find

The businesses I have visited say they struggle finding skilled workers and machinists. Some of them have had open applications for many months or needed to hire workers from out of state to fill the need. According to the US Department of Labor, nearly 70% of high school graduates are going to college.

While on the surface, students getting the opportunity for higher education is beneficial. It does decrease the talent pool for machinists and other tradesmen. The stigma of trade school has hurt companies looking to hire more employees for their machine shop. When a business struggles to staff their shop with the highest quality workers, productivity suffers. Orders are late and production managers have new fires to put out every day. This creates a need for shops to work as efficiently as possible, maximizing the valuable time of skilled labor.

2. Machining Metal Prototypes Takes Time

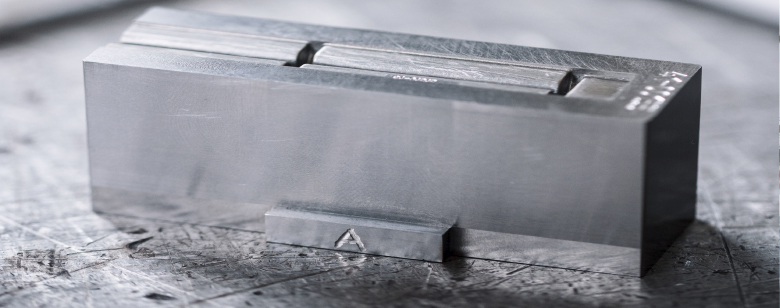

Start with a block of wood, aluminum, or your material of choice. If you need to make a shape more complicated than drilling a couple of holes and cutting material to length, machining takes time. Chances are, whatever you are trying to make requires many operations, and assembly work. Every time your aluminum stock needs to move from the band saw, to the mill, to the surface grinder, it adds time and expense. Unfortunately, engineers have to wait for finished prototypes because of traditional equipment processes. A not-so-modern solution to cutting down on steps is to use a near-net-shape part from casting. But this opens up a slew of other cost-consuming issues around tooling and lead times.

3. Metal Prototypes Aren’t Considered “Value-Added”

Some of the companies I visit place a high value on metal prototyping, but most of them have it on the back burner. Instead of working for the future of their company, they focus on Value-Added Work – making the parts that get sold as a product. This makes sense – after all, they need to keep the lights on by meeting delivery deadlines. As hard as they try, surveys have shown that nearly 90% of manufacturing companies have a backlog of work.

“Nearly 90% of manufacturing companies have a backlog of work”

In this scenario, all hands are on deck, trying to meet deadlines to keep customers happy. Too often, that means that if the equipment was bought for prototyping, it quickly gets “borrowed” instead to make sellable parts. Prototyping gets pushed to the bottom of the priority list, which can create long-term downstream damage to the business. When prospects are forced to wait weeks or months for prototype sample parts, they are more likely to shop around for another source of parts.